Pulling together

In July 2014 the John Lewis store in York made history by

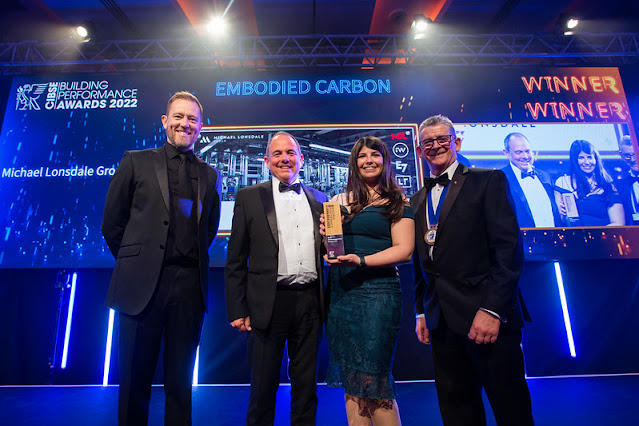

becoming the first department store in the world to be awarded a BREEAM

Outstanding rating – the highest category achievable under the BRE’s

environmental and energy assessment method.This achievement was recognised at the 2016 CIBSE Building Performance Awards where the scheme won the Collaborative Working

Partnership Award. Andy Pearson writes about the secrets to their achievements.

The path to the team’s success started two years earlier in

2011, when JLP announced its commitment to reduce carbon emissions from a 2010

benchmark by 15% in absolute terms by 2020. This is an exceptionally

challenging target when you factor in that the business is growing and adding new shops.

To help achieve its objective the business set a carbon reduction target for its

new shops of 30% less than existing similar shops.

|

| Inside York's award winning John Lewis store |

In 2012, JLP approached consulting engineers Lateral

Technologies & Solutions to develop a building services solution for its

new mid-sized, flexible-format department store in York. This had a target carbon

saving of 30% compared to JLP’s the flexible format Exeter store.

This fabric envelop of the 12000m2 York store was

designed to be airtight to help the design team meet the carbon saving target

by preventing heat and energy leaking through gaps in the building fabric. In

fact, the building’s air permeability was later measured and found to be only 3m3/hr

per m2 at 50Pa, three times better than the Building Regulations

minimum.

To develop its building services solution Lateral

Technologies joined with IES Consulting as its technology partner and building

energy management specialist Next Controls.

|

| The model showed that peak cooling was only needed for 0.1% of the year |

Lateral Technologies used utilities information from

JLP’s Exeter store as a benchmark for the new building and to inform the York

store’s low carbon M&E design. The York store’s airtight building envelope enabled

Lateral Technologies to develop a ventilation solution using an energy

efficient displacement ventilation system serving the retail floors. Displacement

ventilation releases fresh, cool air at floor level; as the air is warmed it rises,

taking with it heat from people, lights and equipment before it is extracted at

ceiling level. To save even more energy, the back of store areas also have the

option of being natural ventilated.

A chiller cools the supply air on days when the outside

air temperature is high. Lateral Technologies was able to optimise the size of

the chiller because it modelled the store using Integrated Environmental

Solutions’ Virtual Environment software. “At this stage we were using the HVAC

module within the IES package, which allowed us to input the control strategies

that we wanted to use to understand their influence on the plant sizes,” says

Iain Gibb, managing director of Lateral Technologies & Solutions.

The software showed that the building had a peak cooling

load of 550kW. Critically, the model also showed that this load was only needed

for 0.1% of the year. It also indicated that if the temperature in the store was

allowed to drift upwards very slightly at times of peak cooling, then a smaller

450kW chiller could be used. The exercise resulted in the installation of chiller

that used 25% less energy to operate.

|

| An energy efficient displacement system serves retail floors |

Lighting was another area exploited by Lateral

Technologies to deliver big energy savings. Front and back of store areas are

lit using LED lighting, which uses 40% less energy than traditional retail

lighting solutions. In addition, sun pipes (effectively mirrored tubes) bounce daylight

from the roof deep into the space to reduce the need for artificial lighting. While

in the storerooms presence detectors automatically turn the lights on and off.

A sophisticated Trend building energy management system (BEMS),

complete with control strategies written by Next Control Systems, was installed

in the York store to control the building services.

The team working really came into its own once the new

store had opened its doors. A number of processes were put in place to ensure

the team could work collaboratively and effectively together to prove that

Lateral Technologies’ innovative building services solution was providing JLP

with the 30% savings it was looking to achieve.

IES had recently developed IES-SCAN, a software solution

created to take data from the building management system and to calibrate it

with the design model. IES provided a secure server on which to host the data

collected from the York store by Next Control Systems. Working in partnership

with the two organisations allowed Lateral Technologies to extract information

from IES-SCAN, via IES’ servers for use in its performance reports. The reports

enabled energy used to be optimised by flagging up systems that were not

performing as expected. “We input the actual performance back into our model to

compare the actual with the theoretical so that we could understand how

accurate our model was,” Gibb says.

The actual results confirmed that the scheme was

performing to within 3% of what the consultant had predicted. In fact Lateral

Technologies design was so successful that the project exceeded JLP’s 30%

target and Lateral Technologies expectations. “We’d predicted a 40% saving and

the scheme actually achieved a 43% reduction in carbon,” says Gibb.

|

| The plant room at the John Lewis store in York |

.png)

Comments

Post a Comment