Embodied Carbon Award: A step towards net zero carbon

Now in its 15th year, the CIBSE Building Performance Awards is the only awards scheme to celebrate the measured performance of projects and products in use while celebrating the engineering consultancies and manufacturers that are contributing to a low carbon future.

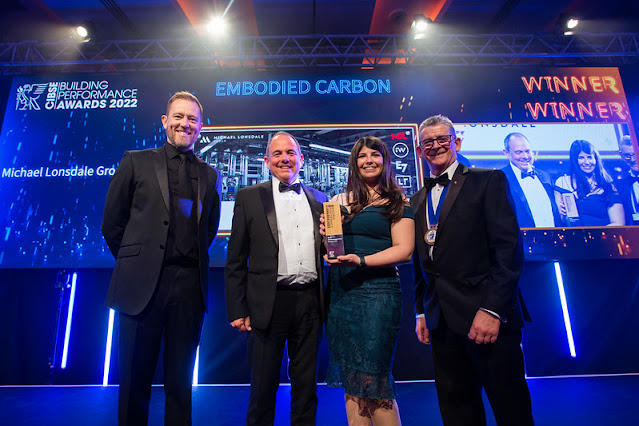

Michael Lonsdale Group won the Embodied Carbon Award for its pioneering work with suppliers to create a database of low embodied carbon products that enable it to recommend low carbon building services systems to its clients.

We heard from Michael Lonsdale Group about what this award means to them:

Industries and businesses throughout the

globe have begun to show ownership of their environmental agendas. The

significance of the topic has been realised, identifying the need for progress

towards Net Zero Carbon. So, when Dame Jo da Silva stated at CIBSE’s Building

Performance Awards that “the Embodied Carbon Award is the award

to have on the night”, this showed the award as a symbol of change in the

industry.

The environmental team first began to look at

embodied carbon not knowing if their work would pay off. Winning this award validates the Group’s proactivity and efforts in facilitating embodied

carbon reduction.

Embodied carbon is a huge factor in the environmental impact of a building. Although it is measured and understood amongst many trade works, there is a known gap in the embodied carbon data of the building services sector. The Michael Lonsdale Group observed that inclusion of this data is key to building a greater understanding of the carbon impact of buildings. If this can be measured and calculated, it can therefore be reduced. Hopefully the industry awakening will align sustainability considerations alongside financial targets, encouraging a brave culture asking: can we afford not to save carbon?

Measuring and reducing embodied carbon is an essential step towards the Net Zero Carbon target - as hard as that feat is. It has a ripple effect, also supporting principal contractors and clients to meet similar, ambitious goals. There is real potential to create a widespread positive impact throughout the industry.

Industry Collaboration

Current project embodied carbon reduction

targets for the building services package are based on limited data and

assumptions. Carbon reduction or product compliance is an advantage as opposed

to being essential, with no consequence to the project if these aren’t reached.

It can be thought of as construction’s own form of greenwashing.

Failing to meet UK carbon reduction targets

though are consequential, as every building that falls short is contributing to

the warming temperatures of this planet. If we are to take sustainability

seriously, we need to have contractual targets regarding sustainable building

and carbon reduction, based on accurate data that drives realistic and

effective outcomes if met.

“It can be thought

of as construction’s own form of greenwashing.”

On the journey of

measuring embodied carbon in the supply chain, there is extensive collaboration

and motivation from manufacturers, reflecting on their carbon impact and

unlocking carbon saving potential. With so many suppliers and product versions

on the market, individual product details need to be calculated for accurate

points of comparison. This has been a challenging process as M&E contractors are not in direct

communication with manufacturers, making it more difficult to collate and

calculate data.

The Michael Lonsdale Group challenges building system design, what products are

being installed and what the true carbon impact of a building will be. With

clear alternatives and innovation options, all levels of construction will

begin to make swifter progress toward using sustainable products and implementing

more sustainable methods of construction.

This progress has led to a healthy database of fantastic products that produce less

carbon in their production, use or disposal. The problem is that even with

these great alternatives provided, often companies are reluctant to implement

them on their project. Often this is due to a products unfamiliarity in the UK

market, even though the product may be tried

and tested in Europe.

Who will be bold enough to take the first leap?

Alternatives and Innovations Schedule

As the embodied carbon

database continues to build, the data has already been put to good use with

several projects. The environmental team review every project using the waste

hierarchy, prioritising methods of prevention before

reduction, reuse or recycling, establishing what

actions can be taken for each project. New build projects negate the

application of reusing existing building materials, however, refurbishment projects

hold opportunities to extend the life of materials with long shelf

lives.

By completing a thorough project specific survey early doors, the environmental team can identify:

- What aspects may be designed to be deconstructed and reused when no longer required?

- What materials can be prefabricated or modular built?

- Which materials can be segregated to aid the recycling process?

Caption:

Prefabrication is crucial to reducing waste on site.

Commercial implications

Sustainable products have a stigma for being costly. In some cases, the product is indeed more expensive. However, what's often overlooked is the added value a sustainable product brings to a building; lower embodied carbon, reduced energy required to function, or reduced carbon emissions output to name a few. The sustainability value of that product may become clearer over time, often negating the initial increased cost of that product.

This highlights a real need to not just look at the initial price of an M&E install, but also factor the initial carbon and carbon impact over time. It’s something the Michael Lonsdale Group already provide in the tender process. Knowledge of the products can be visualised, demonstrating any carbon reductions that partner with the offering. This information is integrated with a series of options that link to various sustainability targets a building aims for.

“The sustainability value of that product may become clearer over time, often negating the initial increased cost of that product.”

Conclusion

Sustainable products

have a stigma for being costly. In some cases, the product is indeed more

expensive. However, what's often overlooked is the added value a sustainable

product brings to a building; lower embodied carbon,

reduced energy required to function or reduced carbon emissions output to name

a few. The sustainability value of that product may

become clearer over time, often negating the initial increased cost of that

product.

This highlights a real

need to not just look at the initial price of an M&E install, but to also

factor the initial carbon and carbon impact over time. It’s something the

Michael Lonsdale Group already provide in the tender process. Knowledge of the

products can be visualised, demonstrating any carbon reductions that partner

with the offering. This information is integrated with a series of options that

link to various sustainability targets a building aims for.

You can see a full write-up from the 2022 CIBSE Building Performance Awards via https://www.cibse.org/policy-insight/news/the-best-in-building-services-engineering

You can find out more about the 2023 Awards via https://www.cibse.org/what-s-on/cibse-building-performance-awards-2023

@CIBSEAwards | #BPA2023 | #BPAWinners | @CIBSE

.png)

Comments

Post a Comment